In today’s fast-paced market, optimising the packaging process is vital for maximising efficiency, reducing costs, and enhancing product attractiveness. Horizontal wrappers are gaining popularity as an innovative packaging solution for a variety of products, offering versatility, speed, and visual appeal. At Australian Wrapping Company, we specialise in providing top-quality shrink wrapping, pallet wrapping, flow wrapping, shrink sleeve applicators, and heat-sealing packaging equipment, tailored to meet your specific packaging requirements.

This comprehensive guide takes you on a journey through the world of horizontal wrappers, delving into their fundamental principles, benefits, types, and applications. With a steadfast commitment to delivering exceptional quality and customer service, Australian Wrapping Company is your go-to destination for all your horizontal wrapping and packaging solutions needs. Embark on this insightful exploration to discover how horizontal wrappers can transform your packaging process, bolster your efficiency, and propel your business to new heights.

Types of Horizontal Wrapping Machines

Horizontal wrapping machines come in varying configurations and automation levels. The two primary types of horizontal wrappers include:

1. Rotary Horizontal Wrappers

In rotary horizontal wrappers, the sealing jaws and cutting units operate in continuous, synchronised motion, enabling rapid packaging operations. Ideal for products that require high-speed packaging, rotary horizontal wrappers are versatile and efficient.

2. Box Motion Horizontal Wrappers

Box motion horizontal wrappers utilise a reciprocating motion for the sealing jaws, ensuring a longer dwell time during sealing. This design is suited for heat-sensitive films or products that demand a robust, hermetic seal, such as pharmaceuticals, fresh produce, or frozen goods.

Benefits of Implementing Horizontal Wrapping

Horizontal wrapping offers numerous advantages that contribute to enhancing packaging operations across various industries:

1. Efficiency

Horizontal wrappers deliver rapid and efficient packaging, capable of achieving speeds of up to 300 items per minute, depending on product type and machine specifications. This efficiency reduces labour costs and minimises human error.

2. Product Protection

Providing a strong barrier against dust, moisture, and other environmental factors, horizontal wrapping safeguards product quality and extends shelf life, maintaining freshness for perishables and ensuring overall product cleanliness.

3. Versatility

Adaptable to a wide range of products with varying shapes, sizes, and materials, horizontal wrappers are compatible with multiple film types and materials, offering a tailored packaging solution to suit any requirement.

4. Cost-Effectiveness

Designed for minimal film waste, horizontal wrappers contribute to reduced material costs and a more sustainable packaging process, benefiting businesses and the environment alike.

5. Enhanced Product Presentation

Horizontal wrapping delivers tightly-sealed, professionally presented packages that boost in-store appeal and bolster retail presentation, attracting customers and increasing sales potential.

Industry Applications for Horizontal Wrapping Machines

Horizontal wrappers serve various industries, driven by their versatile and efficient operation. Typical applications include:

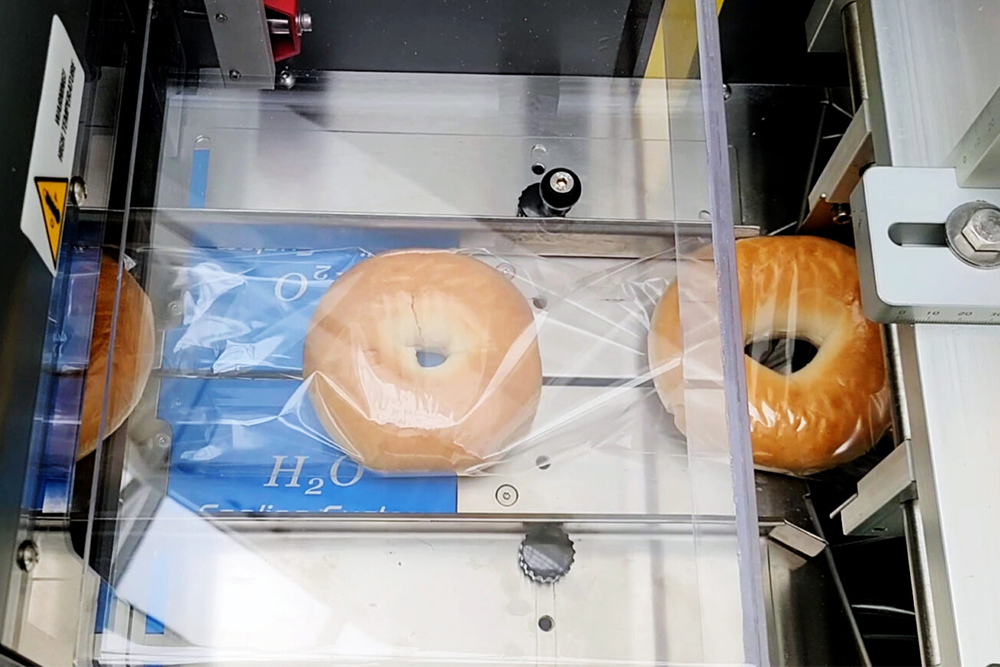

1. Food Products

Horizontal wrapping is popular in the food industry due to its ability to uphold freshness, maintain hygiene standards, and offer visually enticing presentation. Commonly packaged items include confectionery, baked goods, fruits, vegetables, and snack foods.

2. Health and Personal Care Products

Items such as toothpaste tubes, bandages, and disposable razors are typically packaged using horizontal wrappers, providing cleanliness and ease of storage.

3. Pharmaceuticals

Using horizontal wrappers for pharmaceutical packaging ensures secure, tamper-evident seals that maintain product integrity and safety. Applications include blister packs, unit dose sachets, and over-the-counter medicines.

4. Consumer Goods

Ranging from toys and electronics to stationery, horizontal wrappers are utilised for consumer goods packaging, providing effective product protection and enhancing retail presentation.

Maximising Efficiency in Horizontal Wrapping Operations

To optimise your horizontal wrapping operations and harness the full potential of these machines, consider adopting the following best practices:

1. Regular Maintenance and Cleaning

Routine machine upkeep is crucial for sustaining consistent performance, reducing repair needs, and extending equipment lifespan.

2. Staff Training and Safety Procedures

Equip your staff with proper machine operation training and implement safety measures, promoting a safe, efficient, and productive working environment.

3. Appropriate Equipment and Materials Selection

Choose the right equipment and film materials to match your specific product requirements and desired packaging outcomes, maximising efficiency and overall product appeal.

4. Continuous Evaluation and Improvement

Monitor and assess your horizontal wrapping operations, making necessary adjustments to improve productivity, reduce waste, and increase efficiency.

Elevate Your Packaging Process with Australian Wrapping Company’s Horizontal Wrappers

In conclusion, horizontal wrapping machines have revolutionised the packaging industry, offering an efficient, versatile, and cost-effective solution suitable for businesses of all sizes and across various sectors. By understanding the types, benefits, and applications of horizontal wrappers, you can identify the ideal equipment to enhance your packaging operations and ensure outstanding product protection and presentation.

At Australian Wrapping Company, we are committed to delivering the best packaging solutions in the form of superior shrink wrapping, pallet wrapping, flow wrapping, shrink sleeve applicators, and heat sealer packaging equipment. With our unwavering dedication to quality and customer service, we are your trusted partner in the world of horizontal wrapping and beyond.

Discover our extensive range of horizontal wrappers today and take the first step in transforming your packaging process and propelling your business toward new levels of success.